Elementary school class visits EPROPLAST

At EPROPLAST, production, testing, and packaging takes place every day—but this time, we had some very special visitors: a third-grade class from the region was given a behind-the-scenes look at our company and got to see how small plastic pellets are turned into finished PET bottles.

From granulate to bottle – hands-on technology

At the beginning, our employees explained the manufacturing process to the children step by step:

- Starting point: plastic granulate – small granules from which everything is made

- The preform: the “bottle blank,” which looks a bit like a test tube.

- The finished PET bottle: the final shape is created in a matter of seconds during the blow molding process.

PET or glass – which is better?

The direct comparison between PET and glass was particularly exciting:

Which is lighter? Which breaks more easily? What are the advantages?

The children found the answers themselves – with great amazement and enthusiasm.

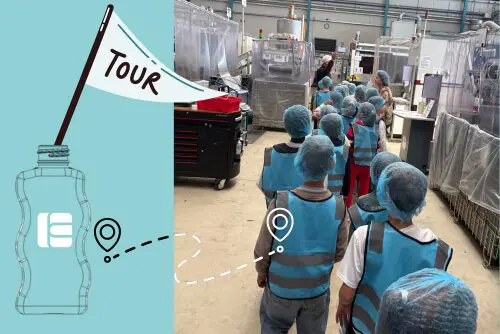

A look at production and quality assurance

After the theory, it was time for some hands-on experience:

the class toured our production lines and quality assurance department, and marveled at the wide range of color samples our customers can choose from. Our large warehouses also caused quite a stir—it's not every day you see so many bottles in one place!

Conclusion

The visit was not only a real highlight for the children—our team also greatly enjoyed combining young curiosity with technology. Perhaps this day even laid the foundation for future plastics technologists or industrial mechanics.

We are already looking forward to your next visit!