Start

Sustainability

Sustainability

Sustainability

Design for Recycling

Basis of our research & development

Dabei denken wir unsere PET-Verpackungen von Anfang an nachhaltig. Jedes neue Produkt wird dank unseres Entwicklungs- und Konstruktionsteams von der ersten Entwicklungsphase an nach dem Ansatz „Design for Recycling“ hin optimiert.

Recyclability considered from the outset

Monomaterial - 100% PET for simple recycling processes

Closures & handles made from 100% PET - Development of closures & handles made from 100% PET

Use of rPET - closed recycling loop with up to 100% rPET content

Recyclable inks - transparent PET & carbon black-free inks for optimum recyclability

Weight optimization - only as much packaging as necessary to conserve resources

What does sustainability mean for Eproplast?

Sustainability in the plastics industry involves acting responsibly throughout the entire life cycle of plastic products. This means that we take care to conserve resources, minimise environmental impact and promote long-term ecological, social and economic balance.

For us as a PET bottle manufacturer, sustainability is a high priority. Through resource-efficient production and the use of recycled PET, we contribute to the design of environmentally friendly packaging solutions.

Dabei ist „Design for Recycling“ die wichtigste Grundlage unserer Forschung & Entwicklung.

After all, we think of our packaging as sustainable right from the start. Every new product is optimised for this from the very first development phase:

- Monomaterial - 100 % PET

- Closures & handles made of 100% PET - increasing mono-material share in bottle-closure combination

- Recyclable inks - transparent PET & soot-free inks for 100% recyclability.

- Weight optimisation - only as much packaging as necessary

We have long recognised that a functioning circular economy requires optimised packaging solutions. Packaging must remain in the cycle for as long as possible and be reprocessed into equivalent products via recycling.

In this way, we not only reduce the new production of plastics but also the impact on the environment enormously.

Sustainable thinking - For our customers

Our sustainable approaches also have a positive impact for our customers, whatever their industry. By providing environmentally friendly packaging solutions, we help them achieve their sustainability goals.

By relying on recycled PET and investing immensely in increasingly energy-efficient manufacturing facilities, we strengthen our customers' image as responsible companies and help them position themselves clearly to act in an environmentally conscious way.

Sustainable packaging is a sign of commitment and innovation, which in turn builds consumer confidence and drives our customers' success.

This is how our customers manage to communicate their sustainability efforts at the POS and offer packaging that meets consumer needs and market demands.

sustainably packaged with PET

Mono material - 100 % PET

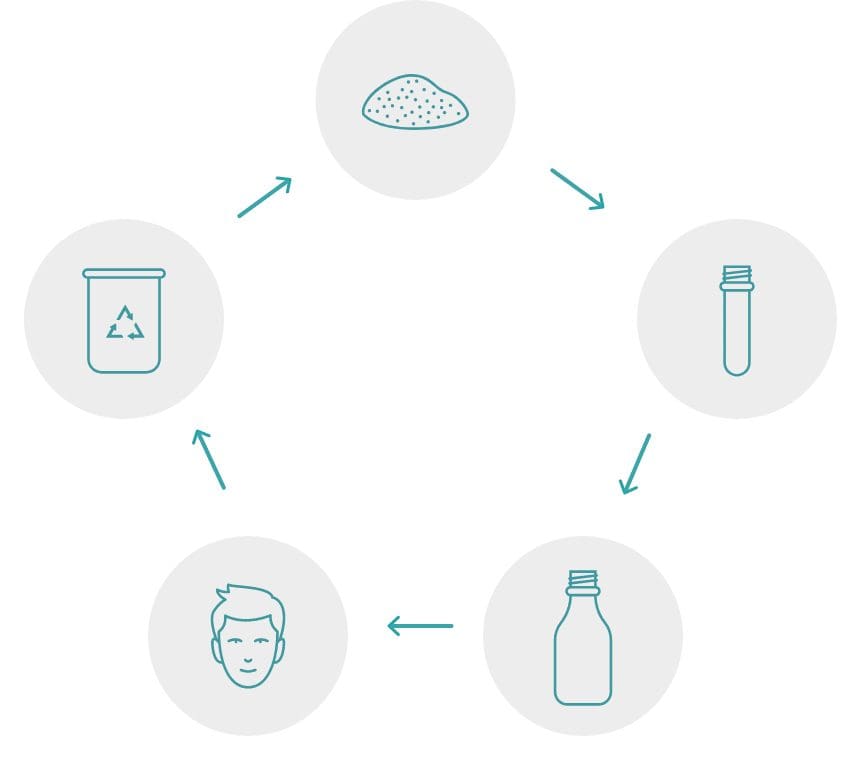

PET bottles are characterized by their ease of recyclability. In contrast to composite packaging, which consists of several complex layers and is therefore more difficult to separate, PET is a mono-material. This simplifies recycling processes enormously. As an important recyclable material, PET can be sorted, cleaned and mechanically recycled. Reusing PET from the recycling loop reduces the use of virgin material.

Doch wir forschen weiter: Bei unserem 5L EPROKANISTER konnten wir mittlerweile auch den Griff auf 100 % PET umstellen. Der Fremdkunststoffanteil der Flasche-Verschluss-Kombination wurde somit auf den Verschluss reduziert.

Recycled PET - conserving resources

Recycled PET plays a key role in reducing our ecological footprint. Every use of recycled PET reduces the use of virgin material.

We can offer you almost all PET bottles from our range with a recyclate content of 30%, 50% or 100%. We assess this individually based on the respective series.

ENVIRONMENT & RESPONSIBILITY / PET REGRANULATE.

PET-Flaschen und PET-Behälter sind umweltfreundliche Verpackungen, die zu 100% wiederverwendet werden können. Wir bei who would mischen zum PET-Granulat auch sogenanntes PET-Regranulat, welches aus dem Wiederverwertungskreislauf stammt. Unsere technisch neueste Anlagentechnik arbeitet energieeffizient und sparsam. Die Abwärme aus unseren Anlagen wird im Winter für die Beheizung unserer Lagerhallen und Büroräume verwendet. Darüber hinaus ist der gesamte Produktionsprozess von PET-Verpackungen um ein Vielfaches energiesparender und umweltschonender als bei der Produktion vergleichbarer Glasprodukte.

WHY NOT 100% RECYCLED?

CLOSED RECYCLING CIRCUIT THROUGH THE USE OF PET RECYCLATE

In the manufacturing process, there is process-related waste due to washing and sorting. This material (caps, labels, packaging bags, etc.) is used for low-grade applications. Therefore, approximately 70-80% of recycled PET is obtained from old bottles. Of course, the quality of the material is not improved by constant recycling.

Today, Quality des Materials verringert sich allerdings durch häufiges Recyceln. Die Molekülketten werden kürzer und damit die Verarbeitung schwieriger. Für eine kontinuielriche Produktion ist es wichtig, dass Neuware mit Rezyklat gemischt wird.

Daher empfehlen wir Ihnen einen Rezyklat-Anteil von 50 %. Natürlich können auch Flaschen mit abweichendem Anteil an Rezyklat angeboten werden.

USE OF PET RECYCLATE

EPROPLAST GmbH offers almost all bottles with an rPET content as an option for bottles made of virgin material. The customer can choose between a 30%, 50% or even 100% rPET content.

The use of recycled PET has an influence on the intrinsic coloration. The transparent material gets a slightly darker shade of gray. Therefore, many bottles with recycled PET are produced with a coloring agent.

Recyclable inks - transparent & carbon black-free

The color of PET packaging influences whether the recyclable material can be quickly and easily detected in a sorting system using a near-infrared scanner (NIR) and thus be sent for further recycling.

Transparent packaging can be reliably detected and can therefore be recognized and sorted for further recycling. PET packaging in the colors green and blue can also be detected quickly and efficiently using the NIR scanners.

Dark colors, on the other hand, make it more difficult to detect and therefore prevent sorting and recycling. Besser ist es hier, auf rußfreie Farben zu setzen, die die Detektierbarkeit nicht behindern und so den Wertstoff im Stoffkreislauf belassen. Wir verwenden bei EPROPLAST ausschließlich rußfreie Farben (carbon free) und setzen somit auch beim Thema Farben ganz auf eine optimale Recycelbarkeit.

Weight optimization - only as much packaging as necessary

After all, even with PET bottles, less is often more. Less weight means less use of virgin material and a lower use of resources.

Use our bottle finder to select the packaging that best suits to your to fits your product. Here you can see the grammages in which we offer our individual bottles. A reduced bottle weight directly results in a reduced use of raw materials.

Long-term thinking - for our customers

Our Design for Recycling approaches also have a positive impact for our customers, whatever their industry. By providing optimized packaging solutions, we help you to underpin your sustainability goals and communicate them to your customers.

In this way, we strengthen our customers' image as responsible companies and support them in positioning themselves through future-oriented action.

Facts about PET

THE ADVANTAGES OF PET PACKAGING

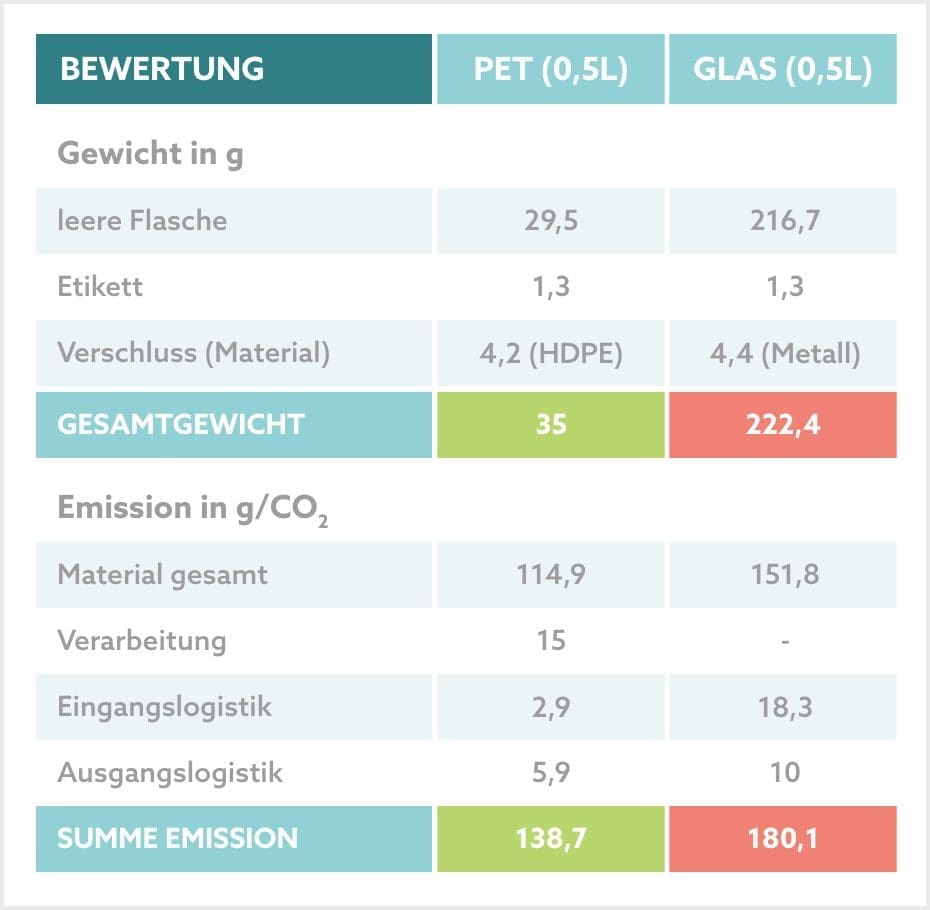

CO2 footprint PET versus glass

Possible alternatives to plastic packaging are increasingly appearing on the market, but on closer inspection they are by no means to be regarded as more sustainable.

Um eine sachliche Diskussion zu den Themen Verpackung und Nachhaltigkeit zu führen, sind Zahlen, Daten und Fakten unabdingbar. Eine der wichtigsten Kenngrößen beschreibt der Wert der CO2-Emissionen. Um eine neutrale Bewertung dieser Kenngröße von einer unserer 500 ml PET Hotfill-Flaschen im Vergleich zu einer gleich großen Glasflasche zu erlangen, haben wir das Unternehmen ClimatePartner in München mit der Erstellung der CO2-Emissionen-Berechnung beauftragt. Unter Berücksichtigung der Rohstoffgewinnung, der Herstellung und der Lieferung bis zum Kunden ergab die Ermittlung der notwendigen Values and the comparison of the results.

PET collection rates at a high level

Taking into account exports of filled bottles abroad and imports of foreign products into Germany, the consumption of PET for beverage bottles was 477 kt. Across all collections (deposit bottles, Petcycle, dual systems, etc.), 456.4 kt of PET was collected again in Germany. This corresponds to a collection rate of 95.7%. If only the collection rate for PET deposit bottles is considered, it is almost 99%. This means that PET as a packaging material has by far the highest collection rate among plastics.

477,0 kt

Total PET beverage bottle consumption in Germany

kt

Total PET bottle collection in Germany

kt

Recycling input in Germany & abroad

kt

Recycling output in Germany & abroad

356,4

kt

Total output rPET in Germany

kt

Usage: Films, fibers & others

121,1 kt

Usage: Bottle to Bottle

A total of around 95% of the PET collected was recycled (rPET) for reuse. Around 34% of the recycled material is used for bottle-to-bottle recycling. The remainder is used for the production of fibers, films, packaging tapes, injection molding applications and non-food PET bottles (cleaning agents, chemicals). The demand for recycled PET in Germany and Europe now exceeds the supply. The sale of used plastics to Asia has practically ceased.

Just to give you an idea of the dimensions. In Germany, a total of 477 kt of PET was consumed for beverage bottles in 2015. In China, the comparable quantity is around 5,000 kt, i.e. more than 10 times as much. Considering that there is no collection system in China comparable to that in Germany, it is clear where marine littering comes from.

5.000 kt

Consumption of PET in China (2015)

kt

Consumption of PET in Germany (2015)

Industry Association of Plastic Packaging

EPROPLAST is an IK member and thus a member of the trade association of the German plastics packaging industry.

The Forum Newsroom Plastics Packaging provides fact-based information and clarification about prejudices and myths surrounding plastic packaging.

Feel free to take a look and learn about the sustainable benefits of plastic packaging.

Find out more facts about the raw materials PET, its advantageous properties and the numerous and diverse applications on the market.

If you have any further questions about PET packaging or PET packaging technology, please do not hesitate to contact us at Contact to enter.